Standards Compliant

ISO 15105-1,ISO 2556,GB/T 1038-2000,ASTM D1434,JIS K7126-1,YBB 00082003

Application Field

Packaging/Food/Medicine/New material/Chemical/Printing

It is used for detecting the gas permeability of various gases such as O?, CO?, N?, etc. in various films and other packaging materials.

It is applicable to the gas permeability performance testing of films, sheets, papers, packaging components and related materials in the fields of food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. It provides a wide range and high-efficiency gas permeability detection for materials with high, medium and low gas barrier properties.

Designed based on the principle of the differential pressure method, the pre-treated sample is placed between the high-pressure and low-pressure test chambers and clamped. Then, the entire test system is evacuated. Finally, the experimental gas is filled into the high-pressure chamber to ensure a constant pressure difference is formed on both sides of the sample. Under the action of the pressure difference, the gas permeates from the high-pressure chamber through the film to the low-pressure chamber. By monitoring the pressure change in the low-pressure chamber, the barrier parameters of the tested sample can be calculated.

1.It has a unique design of the cavity and gas circuit. The volume of the low-pressure chamber can be adjusted according to requirements, and it has a wide measurement range.

2.Imported sensors are used, and the instrument has high precision and good stability.

3.Advanced P.I.D temperature control technology is adopted, and the temperature control precision is high.

4.The curves of transmittance, pressure and temperature are displayed in real time, and the running status of the instrument parameters is tracked in real time.

5.The software interface is simple, and the operation is convenient. Both automatic and manual tests can be selected. The experimental report is automatically saved and can be printed at any time.

6.With a large-scale maintenance-free design, it has excellent performance, can run continuously throughout the year, and is equipped with an over-pressure safety protection function.

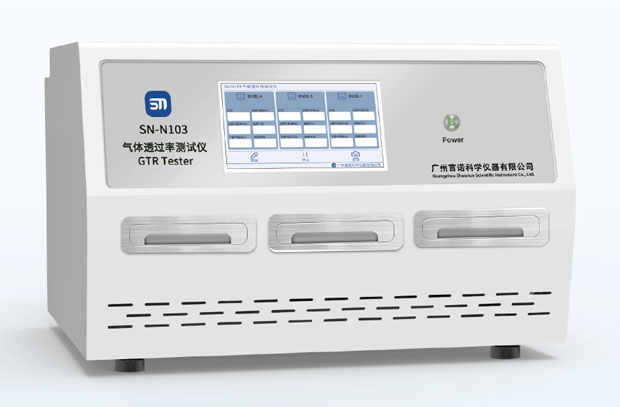

7.The main unit of the instrument is equipped with a touch display human-machine interface, which displays various parameters simultaneously.

|

Item

|

Parameter

|

|

Measurement range

|

0.02 - 50000 cm³/(m²·24h·0.1MPa)

|

|

Measurement accuracy

|

Within ±2% of the indicated value

|

|

Resolution

|

0.01 Pa

|

|

Vacuum degree

|

< 27 Pa

|

|

Sample thickness

|

≤ 5 mm

|

|

Power supply

|

AC 220V/50Hz

|

|

Permeation area

|

50.26 cm² (Other options available)

|

|

Temperature range

|

5°C - 55°C

|

|

Temperature control accuracy

|

±0.5°C

|

|

Experimental temperature

|

23°C

|

|

Test gas pressure

|

0.1 MPa

|

|

Carrier gas interface

|

1/8 inch

|

|

Air source pressure

|

≥ 0.4 MPa

|

|

Air source interface

|

Φ 8mm polyurethane tube

|

|

Dimensions

|

690mm×520mm×450mm

|

|

Three samples can be tested simultaneously. Each chamber can be tested independently and a separate test report can be issued.

|

Instrument Configuration

One main unit, stainless steel pipes, one power cord, air pipes, sealing grease, computer connection cables, a sample cutter, qualitative filter paper,installation accessories.

User Provided

Compressed air (pressure ≥ 0.4 MPa, interface Φ8 mm polyurethane tube), vacuum pump (rate 4L/s, vacuum degree 6×10-2), test gas (O? with a purity of 99.99%) computer.

Deliver,Shipping And Serving

Provide product technical parameters, application scenarios, and other information to help you to choose the right equipment. Solution Design, sample testing, on-site visits is also supported.

Clarify details such as price, delivery time, payment methods, sign the contracts, and provide operation/ maintenance training to ensure customers use the instruments correctly.Assist customers with acceptance procedures and debugging each goods before shipment to ensure the instruments meet contract requirements.

In addition to the 1-year warranty, we also provide lifelong remote technical support to solve usage problems, provide regular maintenance services, and solve specific problems for customers in a timely manner.

Tel:13556033107

Tel:13556033107 E-mail:

E-mail: