Standards Compliant

ASTM D3985,ASTM F1307,ASTM F1927(optional),GB/T 19789,GB/T31354,DIN 53380-3,JIS K7126-2-B,YBB 00082003-2015

Application Field

Packaging/Food/Medicine/New material/Chemical/Printing

It is suitable for the oxygen permeability performance testing of films, sheets, papers, packaging components and related materials in fields such as food, pharmaceuticals, medical devices, daily chemicals, photovoltaic electronics, etc. It provides a wide range and high-efficiency oxygen transmittance detection for materials with high, medium and low oxygen barrier properties.

The principle of the coulometric method is adopted. The pre-treated sample is fixed in the middle of the test chamber. High-purity oxygen flows in the upper chamber of the film, and high-purity nitrogen (carrier gas) flows in the lower chamber. Oxygen molecules diffuse through the film into the nitrogen on the other side and are carried by the flowing nitrogen to the sensor. By analyzing the oxygen concentration measured by the sensor, the oxygen transmission rate can be calculated.

1.High-precision imported oxygen sensor, with high sensitivity, ultra-high stability and extremely low failure rate, and a resolution of 0.0001cm³/(㎡·24h).

2.Accurate and reliable test data: The test temperature is precisely controlled. Equipped with a high-precision temperature sensor, the temperature and humidity in the test chamber are stable, and the temperature control accuracy can reach ±0.5 ℃.The temperature, gas flow values and curves are monitored in real time during the test, and the test has high repeatability.

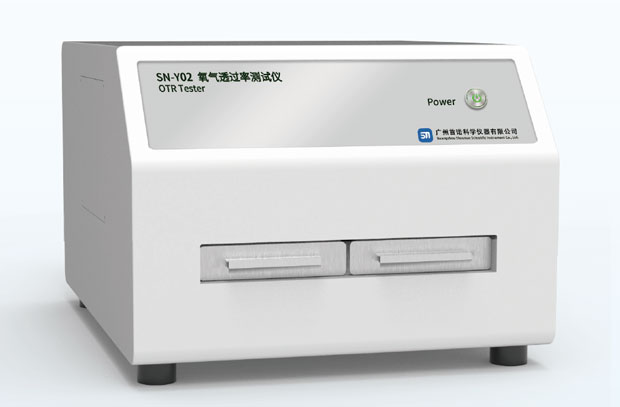

3.Ultra-wide test range and high instrument applicability: The instrument is equipped with a single chamber, which is compact and flexible, saving space; with an ultra-wide test range of [0.005~1000 cm³/(㎡·24h)], it can meet the test requirements of high, medium and low barrier materials. With the addition of suitable accessories, it can measure the oxygen transmission rate of containers such as bottles, bags and bowls.

4.Intelligent operating system with global certification: Self-developed intelligent operating system with modular diagrams, flexible setting of test process parameters, and intuitive and convenient operation; Designed according to the GMP appendix "Computerized Systems", it has an audit trail function and multi-level user authority settings, which can meet the data traceability requirements of the pharmaceutical industry; Personalized test reports can be set as required, supporting various data output formats, and the function of submitting audit reports online.

|

Item

|

Parameter

|

|

Measuring range

|

0.005 - 1000 cm³/(m²·24h)

|

|

Resolution

|

0.0001 cm³/(m²·24h)

|

|

Temperature range

|

5°C - 55°C

|

|

Temperature accuracy

|

±0.5°C

|

|

Carrier gas flow

|

5 - 100 mL/min

|

|

Specimen size

|

Φ 110 mm

|

|

Specimen thickness

|

≤3 mm

|

|

Gas source pressure

|

≥0.4 MPa

|

|

Oxygen pressure

|

0.1 MPa

|

|

Nitrogen pressure

|

0.1 MPa

|

|

Chambers/ Cells

|

2 pieces

|

|

Power

|

450 W

|

|

Power supply

|

AC 220V/50Hz

|

|

Permeation area

|

50.26 cm² (other options available)

|

|

Humidity range (optional)

|

0 - 90%RH (±2%)

|

|

Dimensions

|

470mm × 570mm × 400mm

|

|

Overall dimensions

|

567 mm × 467 mm × 360 mm

|

Instrument Configuration

Power cord, communication cable, sample cutter, sealing grease, 3mm steel pipe

User Provided

Compressed air (pressure ≥ 0.4 MPa, interface Φ 8mm polyurethane tube), one cylinder of oxygen (purity must be over 99.99%, equipped with a pressure reducing valve, output range 0-0.4 Mpa), one cylinder of nitrogen (purity must be over 99.999%, equipped with a pressure reducing valve, output range 0-0.4 Mpa),computer.

Deliver,Shipping And Serving

Provide product technical parameters, application scenarios, and other information to help you to choose the right equipment. Solution Design, sample testing, on-site visits is also supported.

Clarify details such as price, delivery time, payment methods, sign the contracts, and provide operation/ maintenance training to ensure customers use the instruments correctly.Assist customers with acceptance procedures and debugging each goods before shipment to ensure the instruments meet contract requirements.

In addition to the 1-year warranty, we also provide lifelong remote technical support to solve usage problems, provide regular maintenance services, and solve specific problems for customers in a timely manner.

Tel:13556033107

Tel:13556033107 E-mail:

E-mail: